Who Benefits?

Manufacturers who need to shrink-label distinctive or difficult packages from 2-64 ounces, at up to 400 containers per minute

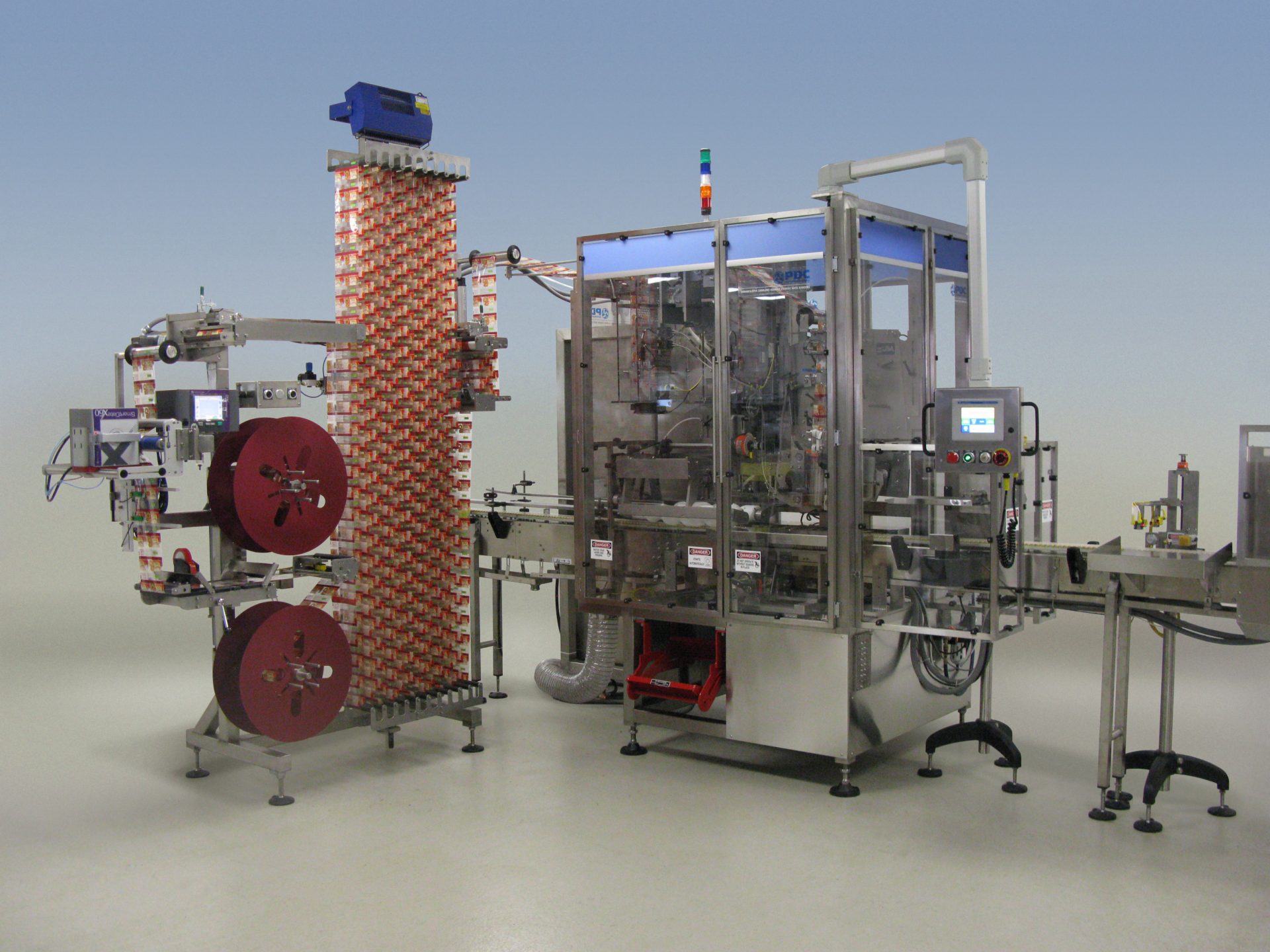

PDC International Corporation, a world leader in shrink seal and shrink label technology for foods, beverages and pharmaceuticals, has introduced a robust, multi-use shrink labeler that processes up to 400 difficult-to-label containers per minute.

The PDC R-300C-TSCB shrink sleeve labeler handles a broad range of challenging package configurations: containers with no taper, thermoformed packs with “flashing”, twin packs, and a wide range of rigid packages. The machine’s applicating head can be either vertical, or easily angled to allow for optimal application on difficult packages. The system accommodates packages with capacities between two ounces and one half gallon.

For challenging applications, the R-300C-TSCB is integrated with special product handling that orients the products in dual counter-rotating timing screws, and then hands them off to servo-controlled gripper belts. This allows precise product handling and the best possible presentation of the packages for sleeving. The servo-controlled cleated belts can decelerate the product during application, then re-accelerate it back to conveyor speed for release to the shrink tunnel.

The R-300C-TSCB is a mandrel-style labeler which uses PDC’s proprietary blade technology – a far more rugged and longer-lived alternative to the fragile “spinning knives” that are standard in most competitors’ equipment. Mandrels, feed screws and other “change” parts can all be switched out quickly thanks to PDC’s exclusive “tool-less” changeover feature and menu driven parameters.

The R-300C-TSCB is ideal for thin films (1.25 to 1.5 mils, 30 to 40 micron), and is compatible with all mono-axial, sustainable and freezer grade shrink sleeve films, including PVC, PET, PETG, OPS and PLA.

Optional features include modules for precise vertical and horizontal consumer perforations, cutoff registration, stainless steel construction and componentry, and splice-on-the-fly accumulators. Auxiliary equipment that can be supplied with the R-300C-TSCB includes conveyors, shrink tunnels and integral inspection modules.

The R-300C-TSCB Shrink Labeler has many important standard features, including a stainless steel frame, upstream photo-eyes, material monitoring sensors and an Allen Bradley CompactLogix PLC platform. Inline quality control inspection systems, printers and bar code verification are also provided for many systems.

Like all PDC machinery, the R-300C-TSCB labeling system is engineered for 24/7 operation, and is made in the USA. It uses standard, widely available components, and is ideally suited for manufacturers and contract packers who want speed, flexibility and reliability in a single “workhorse” system.

For more information, contact Gary Tantimonico, PDC International, Norwalk, CT