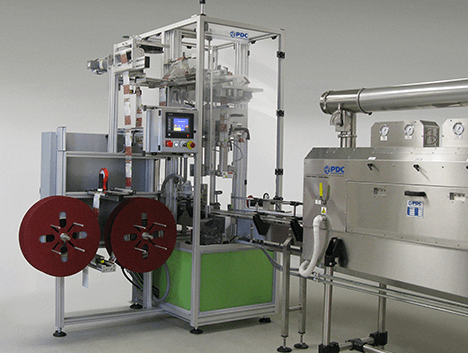

Pack Expo 2016. (North Upper Hall – N-5136) PDC International Corp. has introduced its NEW Model R-100 Evolution Shrink Labeler, an economical and compact system designed for continuous shrink labeling and twin packing. The R-100 is a line extension of PDC’s highly popular R Series of shrink sleeve labelers. What’s different is its popular, moderate speed: 30-100 cpm.

The R-100 is also distinctive in that it has the technological advantage of PDC’s blade assembly, an elegant cutting solution with a service life of months and longer. This proprietary assembly was developed as a longer-lived alternative to the fragile “spinning knives,” that are used in most sleeving systems. PDC’s blade assembly has been tested and proven in dozens of applications, and on virtually every commercial packaging film.

WHO BENEFITS?

Specialty food, beverage, vitamin companies and contract packers looking for a robust, cost-effective system for shrink sleeve labeling and twin-packing.

The R-100 applies full sleeve shrink labels and tamper evident sleeves at speeds of 30 to 100 containers per minute. The system is also capable of twin packing similar containers for club stores or value packs. Containers can be filled or empty, and virtually any size or shape. PVC, PETG, OPS and PLA labels, in gauges as thin as 30-40 micron are all compatible. The R-100 maintains precise graphic orientation for all package shapes.

The R-100 Evolution is a robust system, built for exceptional reliability. Its compact size makes it a practical, economical addition to a production line. Mandrels, feed screws, and other change parts can all be switched out quickly, thanks to PDC’s tool-less changeover feature. Optional construction features include a welded stainless steel frame and complete stainless steel construction.

The R-100 is controlled with an Allen-Bradley MicroLogix 1400 PLC with Ethernet, Red Lion Touch Screen HMI, and stepper motors. Systems can be built with optional modules for vertical and horizontal perforations (important for consumer tamper evidence), and date coding. The standard sensor and verification package (which includes material-out and film feed jam sensors, and upstream photo-eye) can be enhanced to identify jams downstream, fallen bottles, low air pressure and other anomalies, and provide detailed machine status indication.

Two available options that are most valuable in continuous production facilities are a second unwind reel and an articulating splice table for precise roll splicing. Conveyors, inspection systems and shrink tunnels, (dry heat or steam) can be supplied as part of an R-100 system.

For more information, contact Gary Tantimonico, (203) 853-1516 or sales@pdc-corp.com. PDC International Corporation, Norwalk, CT. www.pdc-corp.com